SPECIFICATION: COMPATIBLE TO IS 13778 (PART 5) 2012 / IEC

60851-5 1985

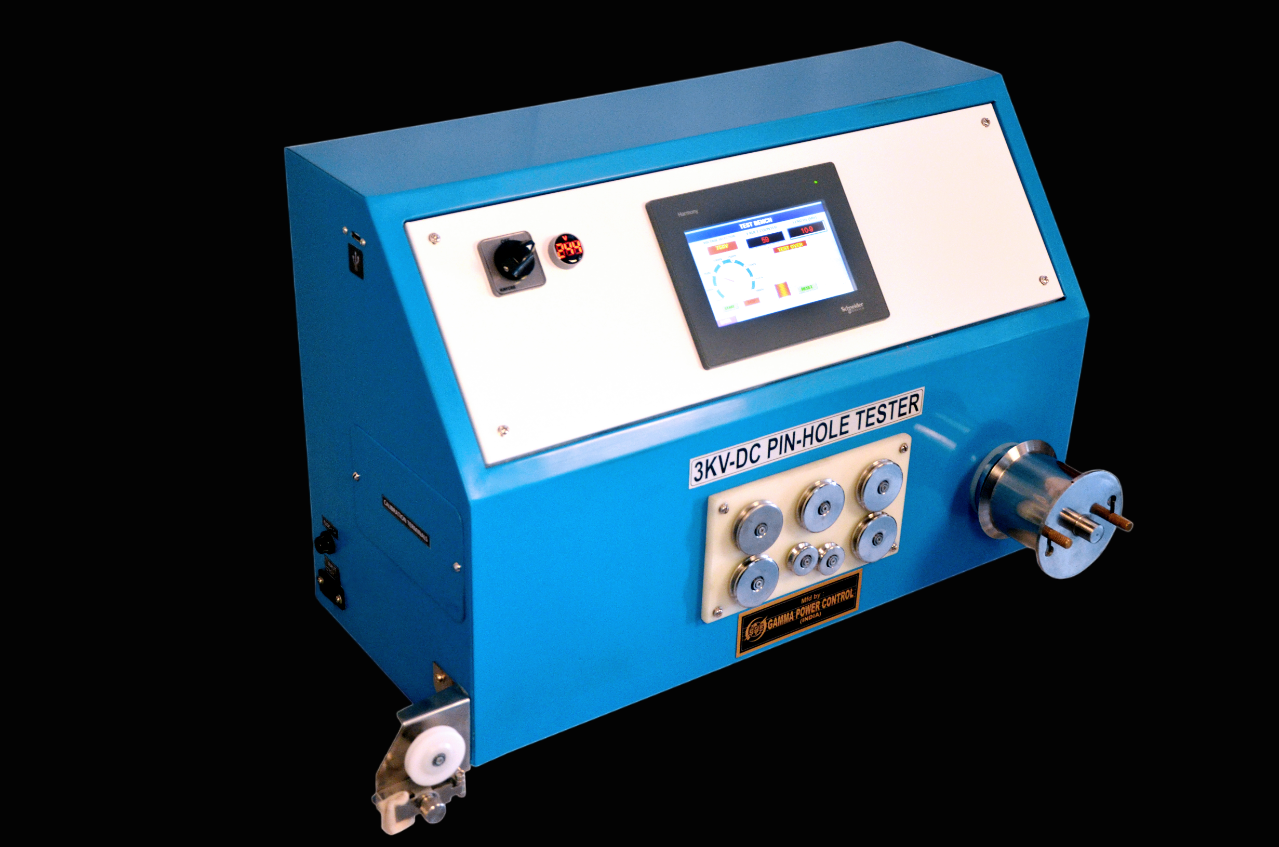

The insulation testing unit offers continuously variable DC voltages up to 3000V across 8 precise steps: 350V, 500V, 750V, 1000V, 1500V, 2000V, 2500V, and 3000V. It operates at a controlled wire speed of 18 meters per minute with a tolerance of ±1 meter. Equipped with a fault detection circuit compliant with industry standards, it detects failures with sensitivities ranging from 5µA, 6µA, 7µA, 8µA, 10µA, 12µA, 14µA and 16µA. The steady state short circuit current is limited to 25 ± 5µA. The unit responds at a rate of 500 counts per minute to detect faults when a bare wire passes over the electrodes. It features auto-stop functionality and is fully automated with all parameters displayed digitally, ensuring precise and efficient testing operations.

SPECIAL FEATURES:

- HMI-Touch Control Display: Equipped with a programmable logic controller and a touch control display for intuitive operation and monitoring.

- Suitable for Diameters Range 0.05 up to 1.6 mm: Designed to test wires with diameters ranging from 0.05 mm to 1.6 mm, ensuring versatility in application.

- V Groove Pulley Angles Made as per IEC and NEMA Standards: Pulley angles are engineered according to international standards (IEC and NEMA), ensuring compatibility and reliability in wire testing.

- Surge Damping Resistor of 4.7 MΩ ± 10% Installed: Installed in the high-voltage line to dampen surges, ensuring stable operation and safety during testing.

- Continuous Fault Signalling Buzzer: Alerts operators continuously in case of faults, ensuring prompt response to any issues detected during testing.

- Test Result Data Storage (Up to 5000 Results): Capable of storing up to 5000 test results, facilitating record-keeping and analysis of testing outcomes.

- Threshold Current as per IEC and NEMA Standards: Adheres to specified threshold current standards (IEC and NEMA), ensuring compliance and reliability in fault detection.

- Stainless Steel Electrode Pulleys and Winding Glass: Electrode pulleys and winding glass components are made from stainless steel, ensuring excellent connectivity and durability.

- 99.9% High Voltage Safety: Provides high-level safety assurance (99.9%) during high-voltage testing, crucial for protecting operators and equipment.

- High Quality Acrylic Polyurethane Enamel Paint: Coated with high-quality acrylic polyurethane enamel paint for enhanced durability and resistance to environmental factors.

- Audible and Visible Fault Indication System: Equipped with both audible and visible indicators to signal faults, ensuring clear and immediate notification of issues detected.

- 500 Pulses per Minute Circuit: Features a circuit capable of generating 500 pulses per minute, contributing to efficient and accurate testing processes.